Leading 3D printer OEM Stratasys has introduced a new full-color PolyJet machine. The J720 Dental can 3D print ultra-realistic dental models using 500,000 color combinations.

Barry Diener, Dental Segment Sales Leader, Stratasys, said, “Labs today operate in a very competitive space where differentiation counts on mastering the digital workflow and expanding into new products and services,”

“THE J720 DENTAL 3D PRINTER IS DESIGNED TO CHANGE THE GAME – ALLOWING LEVELS OF SPEED, PRODUCTIVITY AND REALISM THE MARKET HAS NEVER SEEN. THIS POWERS LABORATORIES TO MEET THE DEMANDS OF A COMPETITIVE MARKET AND PUSH THE BOUNDARIES OF DIGITAL DENTISTRY.”

3D printing in the dental industry

The dental industry is among the earliest adopters of 3D printing technology and, as such, it has become a key vertical for many competing OEMs in the sector.

Traditionally, dental models and prosthetics are either machined or made using investment casting processes. However, these methods are not capable of manufacturing the highly complex shapes that 3D printing can. Moreover, the high precision of dental models also ensures a better quality of the treatment as 3D models can be used as guides in dental surgery.

In recent times, DLP/SLA 3D printers such as the NexDent5100 by 3D Systems, Form 2by Formlabs and EnvisionTEC’s Vida cDLM have prevailed in the dental industry, due to their high accuracy and speed.

According to Stratasys, the J720 Dental can match the speed and quality of DLP/SLA 3D printers and is a direct competitor to the technology in the dental market.

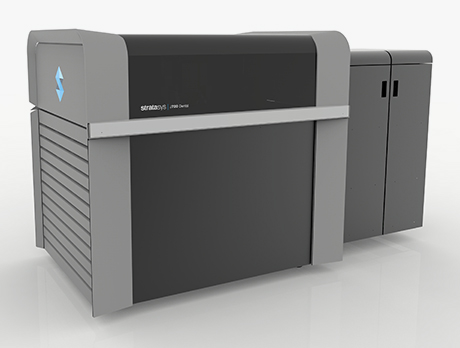

J720 Dental 3D printer

The J720 Dental has a large build size (490 x 390 x 200 mm) and an accuracy of up to 200 microns. It can print in full-color using various materials, which can mimic the shape, texture, and color of teeth and gums.

Some of the materials supported by the J720 include MED610, a clear biocompatible material, certified for temporary in-mouth placement, and VeroDentPlus (MED690), a highly durable beige color material. Furthermore, the J720 can also print soluble support materials which ensure that the model’s accuracy is not compromised by the support structure.

On the software side, the J720 Dental is maintained by GrabCAD Print which can create a gcode directly from a CAD model, without the need to convert the CAD to an STL file. This can speed up the production process as the conversion to STL often generates errors in the mesh file which takes time to fix. Furthermore, the GrabCAD Print lets the user manage multiple printing jobs and monitor the printing process to minimize print failures.

The J720 Dental is currently on display at one of the largest dental laboratory event, LMT Lab Day Chicago (February 22-23) at Booth A9.

Source: 3dprintingindustry