Italian 3D printer manufacturer Roboze will be showcasing its high temperature ROBOZE Xtreme series for the first time in North America at RAPID+TCT 2019. The exhibition, this year held in Detroit, will take place later this month from the 20th to 23rd of May.

According to Alessio Lorusso, founder and CEO of Roboze, “In terms of demand, the North American is one of the most important markets for Roboze.”

“THE TECHNOLOGY WE OFFER IS THE ANSWER THAT TODAY US BUSINESSMEN ARE LOOKING FOR TO STRENGTHEN THEIR PRODUCTIVITY WITH HIGH TEMPERATURE AND COMPOSITE MATERIALS FOR THE PRODUCTION OF FINISHED PARTS WITH THE MAXIMUM PRECISION.”

The new ROBOZE Xtreme series made its debut at Formnext 2018, and features the ROBOZE One Xtreme and ROBOZE One+400 Xtreme 3D printers. Both systems work using the company’s patented Beltless System, designed for precise, industrial-use projects, and its High Viscosity Polymers (HVP) extruder.

The ROBOZE Xtreme series

The ROBOZE Xtreme series was created to bridge the gap between Roboze’s production additive manufacturing system, the Argo 500, and desktop-sized 3D printers, the ROBOZE One and ROBOZE One+400. As such, the One Xtreme and One+400 Xtreme are dubbed “desktop/production systems.” What this means is that the capabilities of the large-scale Argo 500 have been replicated in the Xtreme series across a smaller footprint. The classification as defined by the company is designed to bring the systems “closer to the needs of the manufacturing sector,” i.e. producing lightweight polymer parts with a strength to comparable metal.

One of the ways desktop/production is achieved in the Xtreme series is through an upgraded Beltless System. The racks and helical pinions of the system are machined with chemical nickel plating increasing the precision of X/Y axis by 15μm, as well as providing improved corrosion resistance. For comparison, previous Beltless System 3D printers from Roboze used racks and helical pinions made from tempered steel, providing a 50μm layer accuracy.

Another upgrade in the Xtreme series, when compared to standard ROBOZE ONE and ONE+400 models, is the inclusion of the company’s High Viscosity Polymers (HVP) extruder, facilitating the processing of more challenging materials.

Both Xtreme Series 3D printer have larger build volumes than the desktop ROBOZE One and ROBOZE One+400 too. In the One Xtreme the build plate measures 300 x 250 x 200 mm, and in the One+400 Xtreme it measures 300 x 250 x 220 mm. For comparison, their predecessors measure 280 x 220 x 200mm.

Each Roboze XTREME 3D printer is completed by a Support System Cabinet (SSC), designed for the reduction of machine vibrations, to control moisture level and handle pre-heating. A Vacuum Box for vacuum generation is housed inside the SSC. This provides adhesion to the print surface, improved first-layer flatness, and cool-down of the HVP extruder.

Super and techno-polymers

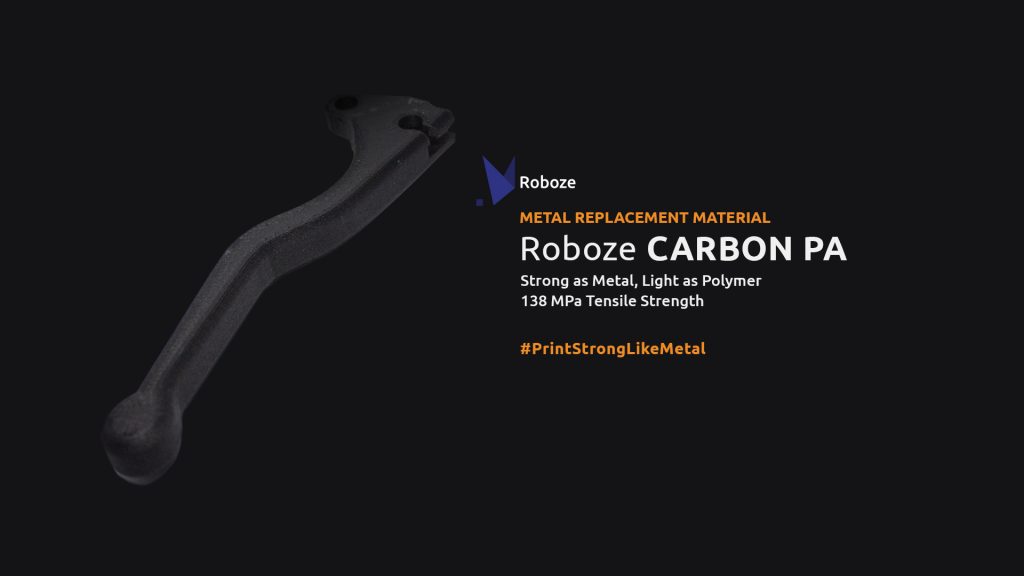

Roboze’s range of materials has also expanded with the Xtreme series. Now, 12 different materials, terms “super-polymers” and “techno-polymers,” are available including Glass PA, PP, Carbon PP and Carbon PEEK.

Additionally, Roboze is providing ULTEM AM9085F filament provided by SABIC. ULTEM AM9085F is a high performance amorphous polyetherimide filament based on SABIC 9085 resin. Part of the “techno-polymer” range, this material provides excellent thermal properties, exceptional dimensional stability, flame retardancy and good chemical resistance. The high performing characteristics give engineers exceptional flexibility and freedom for prototyping as well as end-use parts.

The benefits of ULTEM, as well as the Xtreme series will be discussed at Roboze’s RAPID + TCT 2019 booth no. 1665. For North American resellers interested in the new range of systems ROBOZE will also be offering a free 60 day trial of the Roboze One+400 XTREME at the show.

“RAPID +TCT will give us the opportunity to show the North American market the best of our 3D printers,” Lorusso adds.

“It will offer us the chance to create new and interesting synergies, aiming at meeting the strong need of 3D printing solutions with high temperature superpolymers and composite materials for metal replacement.”