Pushing the boundaries of additive manufacturing, engineers at Royal Melbourne Institute of Technology (RMIT) University have developed a new 3D-printable titanium alloy that is 29% cheaper to produce than aerospace-grade titanium, offering a leap forward in performance, ductility, and cost-efficiency by eliminating reliance on increasingly expensive vanadium.

Valued for its high strength-to-weight ratio and corrosion resistance, titanium has emerged over the past century as a critical material in aerospace, medical, and advanced engineering.

Despite its advantages, however, the metal remains costly to process and difficult to adapt – particularly for next-generation manufacturing technologies like 3D printing.

This is primarily due to the material being used in alloys developed for traditional processes such as casting and forging, which do not respond predictably to the concentrated heat input and rapid cooling cycles of additive manufacturing.

With industries demanding lighter, stronger, and more affordable components for everything from medical implants to deep-space systems, a fundamental shift is underway to rebuild titanium from the atomic level up – and RMIT researchers may have just taken a pivotal step forward.

As part of its work at RMIT’s Centre for Additive Manufacturing, a research team led by PhD candidate Ryan Brooke has developed a titanium alloy tailored specifically for additive manufacturing.

“3D printing allows faster, less wasteful and more tailorable production yet we’re still relying on legacy alloys like Ti-6Al-4V [90% titanium, 6% aluminum, and 4% vanadium] that doesn’t allow full capitalization of this potential,” said Brooke. “It’s like we’ve created an aeroplane and are still just driving it around the streets.”

That limitation, according to Brooke, has less to do with the printing technology itself and more to do with the outdated alloys it is expected to process.

“New types of titanium and other alloys will allow us to really push the boundaries of what’s possible with 3D printing and the framework for designing new alloys outlined in our study is a significant step in that direction,” he added.

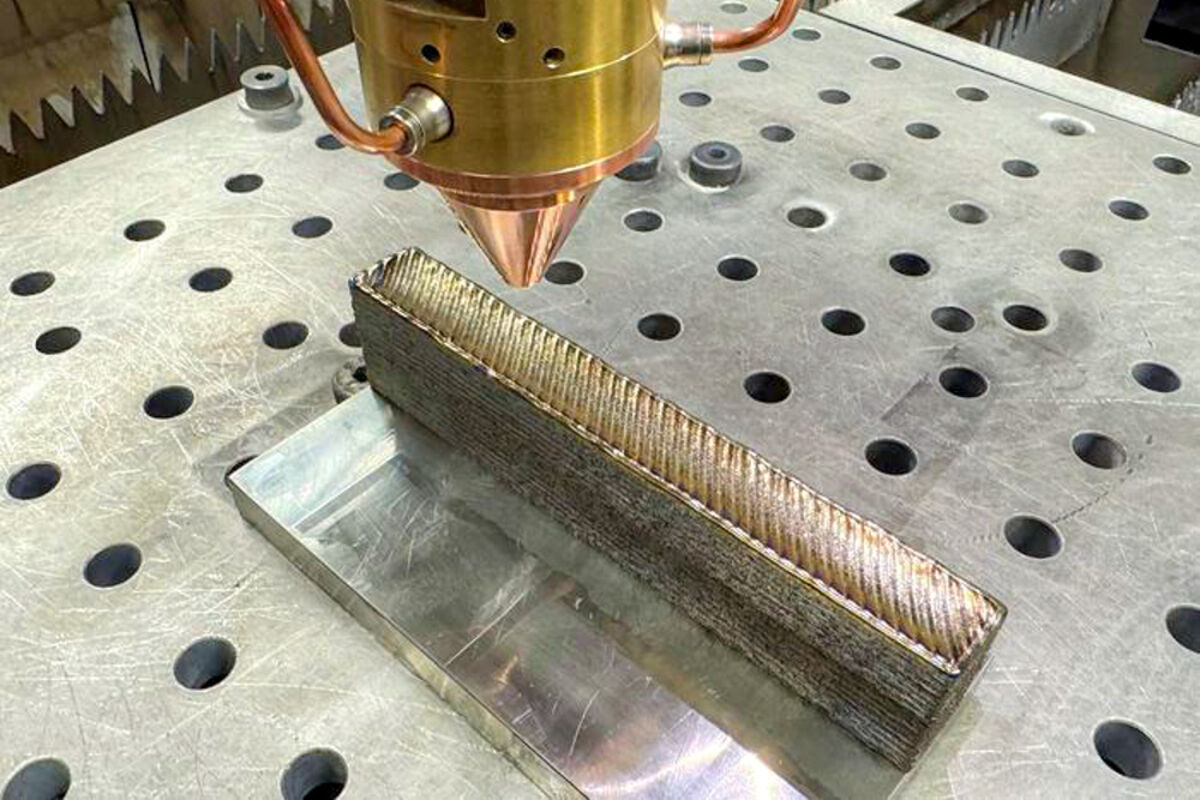

Michael Quin, RMIT University

A sample of the new stronger, cheaper 3D printed titanium.

Developed through a predictive design framework, the composition introduces lower-cost, readily available alternatives in place of vanadium – an increasingly expensive element used in conventional formulations – and enables more uniform printing by avoiding the column-shaped microstructures that lead to uneven mechanical properties in some 3D-printed alloys, all without compromising strength or ductility.

“By developing a more cost-effective formula that avoids this columnar microstructure, we have solved two key challenges preventing widespread adoption of 3D printing,” said Brooke. “What I heard loud and clear from end users was that to bring new alloys to market, the benefits have to not just be minor incremental steps but a full leap forward, and that’s what we have achieved here.”

Samples of the alloy were produced and tested at RMIT’s Advanced Manufacturing Precinct, where the team evaluated both structural consistency and mechanical performance under additive conditions.

The results informed a provisional patent filing and supported the publication of the research in Nature Communications, where the alloy’s design framework was outlined as a scalable method for accelerating the development of next-generation printable metals.

Study co-author and RMIT professor Mark Easton said advancing the technology would require broader coordination across the manufacturing and materials supply chain.

“We’re very excited about the potential of this alloy,” he said, “but turning it into a successful product will take collaboration, and we’re actively looking for industry partners to help guide the next phase of development.”