GE Additive’s Concept Laser metal additive manufacturing technology has been leveraged in the development of a hybrid dental abutment to be launched by an oral implantologist at IDS next week.

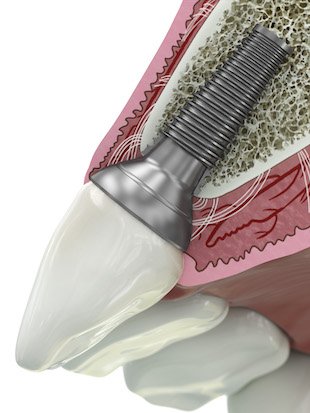

Prof. Dr. Mario Kern is set to debut his ‘Extended Anatomic Platform’ (EAP) in Cologne, which has been designed to counter the growing presence of peri-implantitus, an infectious disease that causes the soft tissue around the implant to recede and makes the metal abutment visible.

With more and more patients being fitted with dental implants, the ailment is becoming increasingly common. Causes include the design and roughness of the implant, and external morpohology, excessive mechanical load. The condition can be worsened by the prior health of the soft tissue. The go-to solution has been to fire a piece of ceramic to where the metal is visible, which can become loose fairly easily, and isn’t thought to be especially aesthetically pleasing either.

Granted patents in Europe, Canada and Australia, the EAP method features different geometry and incorporates ceramic behind the metal, with a bowl design enabling the ceramic to sit much lower. Should gums recede, the metal can simply be removed to see the ceramic again. Additional modifications are always possible because the design-related glue joint of the abutment can be quickly displaced coronally, and EAP is said to be more biocompatible with better cell attachment, enhanced ease-of-use, and a higher aesthetic appeal.

With a better reduction of cytotoxic influence on the glue joint, cells attach to the abutment, enabling the formation of biological width. Offering a larger surface also guarantees solid cell attachment, as does the 0.2 to 0.5 µm surface roughness of the EAP abutment. Final restorations can be made either with analogue methods or digital CAD/ CAM techniques, and crowns can be co-manufactured in one piece, either as full ceramic of PFM crown.

The EAP structures, which connect a crown, bridge or removable denture to the dental implant fixture, are additively manufactured with an Mlab cusing 200R, before being milled with a Georg Fischer machine. The abutments cannot be milled entirely because of their thin wall structures. Both the printing and milling processes are controlled with Follow-Me hyperDENT software, a platform which features automatic nesting, automatic generation of ID tags for part identification, and the automatic generation of the machining allowance for milling. Through this process, Dr. Kern has achieved 85% material savings, 50% time saved in production, and a 99.6% density of the final product.

“The dental hybrid process enables economical production of my abutment with highest accuracy,” commented Dr. Kern. “With its dental expertise and technical solutions, GE Additive is the perfect partner for my business. This solution combines the advantages of additive manufacturing with subtractive technology, to get the best out of both manufacturing worlds, which means a time and cost-efficient production process.”

Source: tct magazine