Ai Build, a London-based AI and automated 3D printing specialist, has introduced a real-time quality inspection tool. Using computer vision and AI, the new feature of the AiMaker fleet will help improve the accuracy of large-scale 3D printing projects.

According to Daghan Cam, CEO of Ai Build, “The milestone we are announcing today is a result of our obsession for flawless production and a major leap towards fully automated, autonomous factories of the future,”

“WE ARE EXCITED TO SEE HOW THE PRODUCTIVITY OF OUR USERS WILL INCREASE WITH THIS ADVANCED TECHNOLOGY.”

Factory of the future

Ai Build’s portfolio includes AiMaker, an AI equipped robotic arm, AiCell, an enclosure for the AiMaker, and AiSync, a cloud-based software for remotely controlling a fleet of AiMakers at a factory anywhere in the world. Currently, these products are available through a monthly or yearly subscription, which ranges from Basic to Professional Combo. The latter includes the full range of Ai Build products and a robotic arm by Kuka.

Large-scale and extrusion based, Ai Build’s AiMaker solution has been implemented in a number of projects including work for the Venice Biennale.

Real-time quality assurance

At any point in the process of 3D printing quality issues can arise. If undetected, such issues can make a print unusable and hours of manufacturing go to waste. As Cam explains, “We have a simple rule at Ai Build: If a product is faulty, we repeat production. If it has a small defect, we repeat. If we are slightly in doubt, we repeat. This level of perfection in additive manufacturing usually comes at a high cost, in the form of excessive labour and material waste.”

To counter quality issues, many companies have integrated real-time quality monitoring systems. Such systems can either revise the machine’s parameters based on data or require human intervention. In both cases, printing errors can be fixed and significant amounts of time and costs can be saved.

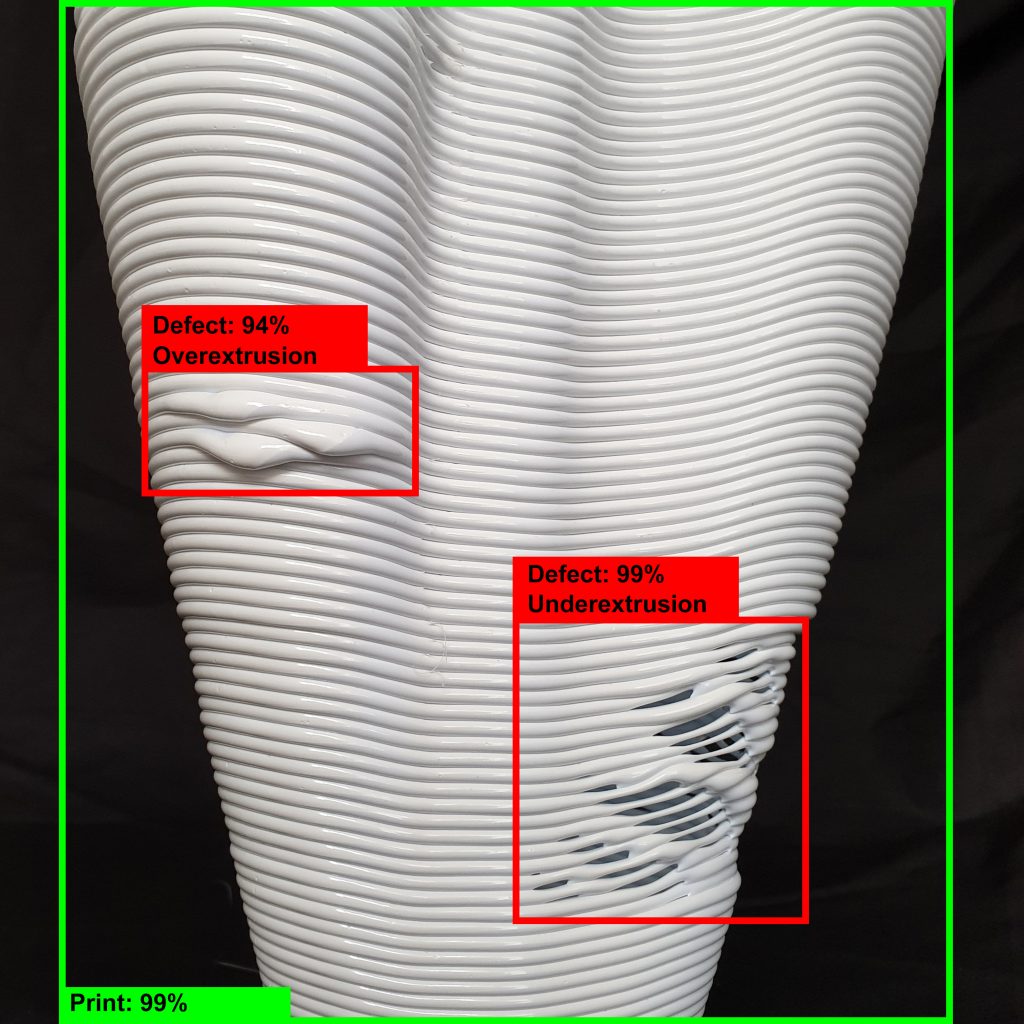

Ai Build’s AiMaker platform is now fitted with a camera and a GPU module that compares images of an in-process part with previously printed objects. If the quality of the 3D print in the process is not up to standard then AiMaker sends a notification to the AiSync.

Leonidas Leonidou, Ai Build’s Head of Applied Research, explained, “By detecting printing defects in real-time, our AI technology offers the potential of automating quality control, while at the same time acting as a form of feedback to the designer about the printability of their design and how such printing issues could be eliminated in future prints.”

The QA enabled 3D printers will begin shipping in the second half of 2019. The technology will be showcased at the AI Summit taking place between 12th-13th June in London.

Source: 3dprintingindustry