Aerosint, an SLS 3D printer manufacturer based in Belgium, and Aconity3D, a German metal 3D printer manufacturer, have partnered to further development of Laser Powder Bed Fusion (LPBF) technology.

The partners are ultimately aiming to implement Aerosint’s re-coating technology into the AconityONE LPBF 3D printer. This collaboration will also research multi-material 3D printing using LPBF. Edouard Moens de Hase, co-founder and managing director of Aerosint, said:

“We are truly excited to partner with an OEM that has the same DNA as we have at Aerosint. Aconity is innovative and driven to solve challenges that haven’t been addressed yet. Together we have all the technical expertise needed to develop very unique LPBF hardware and multi-metal applications.”

Aerosint & multi-material 3D printing

According to Moens de Hase, Aerosint began as a research endeavor in early 2015 as part of the Belgian startup studio Make.it. The company was established to reinvent the technical approach in powder fusion-based additive manufacturing, opening up an increasingly competitive market.

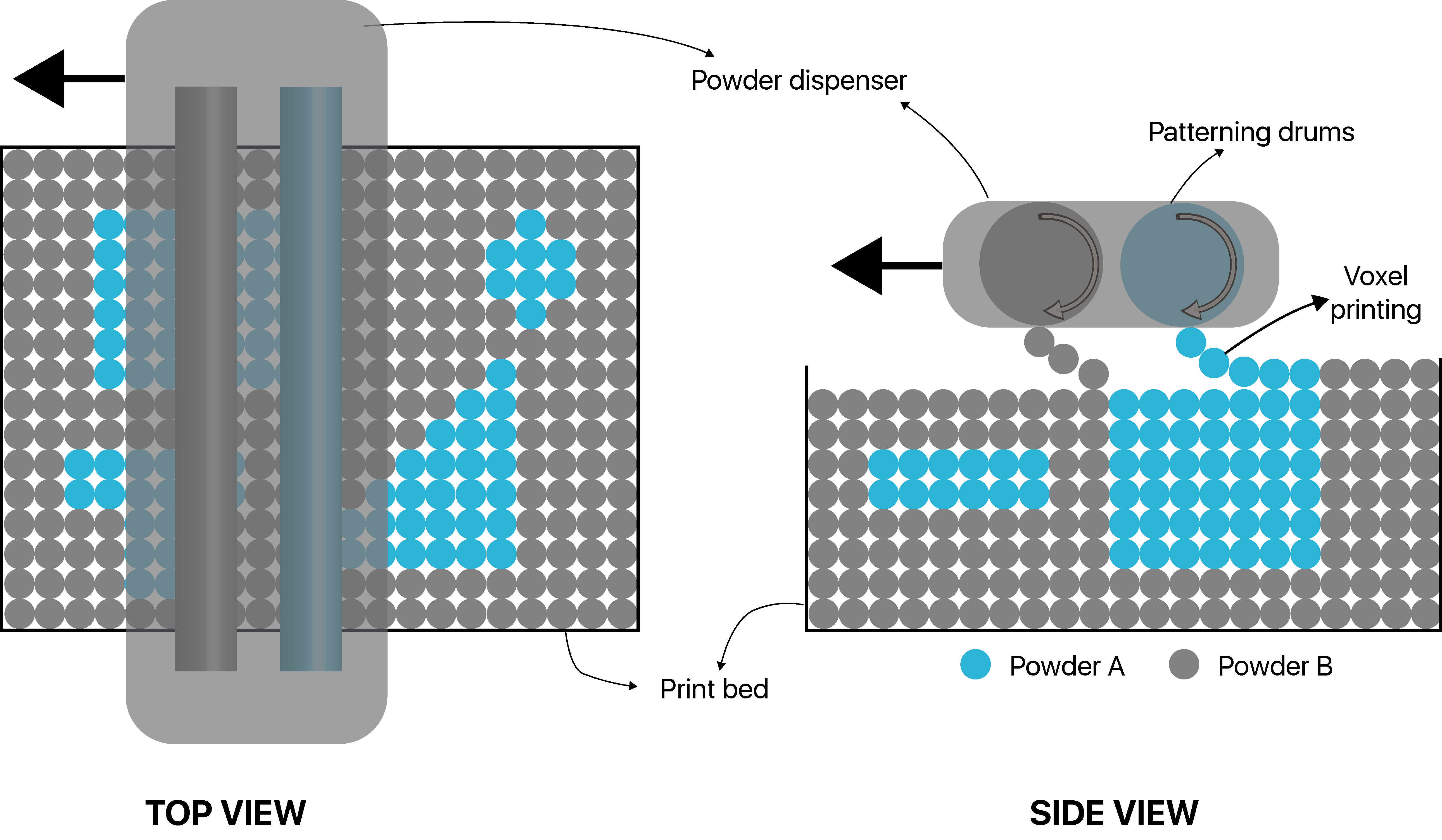

Last year, Aerosint was announced as one of eight challenge winners in the 2018 Formnext startup challenge. Prior to this, the company closed an €850k financinground to further develop its selective powder deposition technology. This process enables successive layers of powder composed of more than one powder, i.e., polymers, ceramics, metals.

“What Aerosint has invented is very unique. An LPBF system with multi-material capabilities is unseen in the industry,” added Yves Hagedorn, CEO of Aconity3D.

“OUR CUSTOMERS HAVE BEEN WAITING FOR THESE CAPABILITIES AND WE ARE THEREFORE EXCITED TO START WORKING ON A POTENTIAL SOLUTION FOR THEM. MULTI-MATERIAL IS FOR US THE NEXT EVOLUTION OF 3D PRINTING AND WE ARE HAPPY WE CAN BE PIONEERS HERE TOGETHER WITH AEROSINT.”

Aersosint believes that its technology can create massive opportunities for 3D printing for rigid prosthetics with localized flexible cushioning for more patient comfort, and for creating colorful models such as toys.

Furthermore, last year, Aconity3D expanded into the US with a new North American headquarters in El Paso with the University of Texas at El Paso (UTEP). Following this expansion, Hagedorn told 3D Printing Industry, that the company targets the market of metal 3D printers.

“The high flexibility of the systems has proved to be a major enabler for expanding the current state of the art in this new technology. Therefore, we are currently mainly active in the field of research systems, either for universities or larger corporations.”

“However, the high modularity of the systems allows for providing customer-specific or better industry-specific solutions for series applications such as medical, aerospace, energy or automotive.”

Moreover, both partners applications will seek to develop new applications for LPBF technology. If successful, the Aerosint’s 3D printer will be made available to Aconity’s customers on the machines options list.

Source: 3dprintingindustry