The European Federation for Welding, Joining and Cutting (EWF) has launched an international education, training and qualification system for additive manufacturing personnel. Divided into two levels, one for operators and one for engineers, the system currently provides qualifications relating to the application of DED and PBF.

One of the main benefits of this system is that qualification can be awarded in any country. As stated in the course catalog, the system focuses on developing crucial skills that are “ready to be applied at local and global operations in areas such as Industry 4.0 and one of its main pillars: Additive Manufacturing (AM).”

“Due to the engagement with various AM stakeholders,” it continues,

“EWF IS ABLE TO BUILD QUALIFICATIONS THAT ARE AN ADDED-VALUE TO THE SECTOR AND TO THE ONES INVOLVED IN THE SYSTEM.”

To further address workforce development for additive manufacturing, EWF is also hosting a survey to discover the skills required of job candidates. Submissions to the survey are open now until September 15 2019.

Become a qualified additive manufacturing system operator or engineer

EWF’s qualifications are specific to metal additive manufacturing and currently cover skills required for laser powder bed fusion (LPBF), laser based directed energy deposition (DED), and arc DED. Other qualifications, including those for designers, supervisors, and operators or engineers for other metal 3D printing methods, are planned for the future.

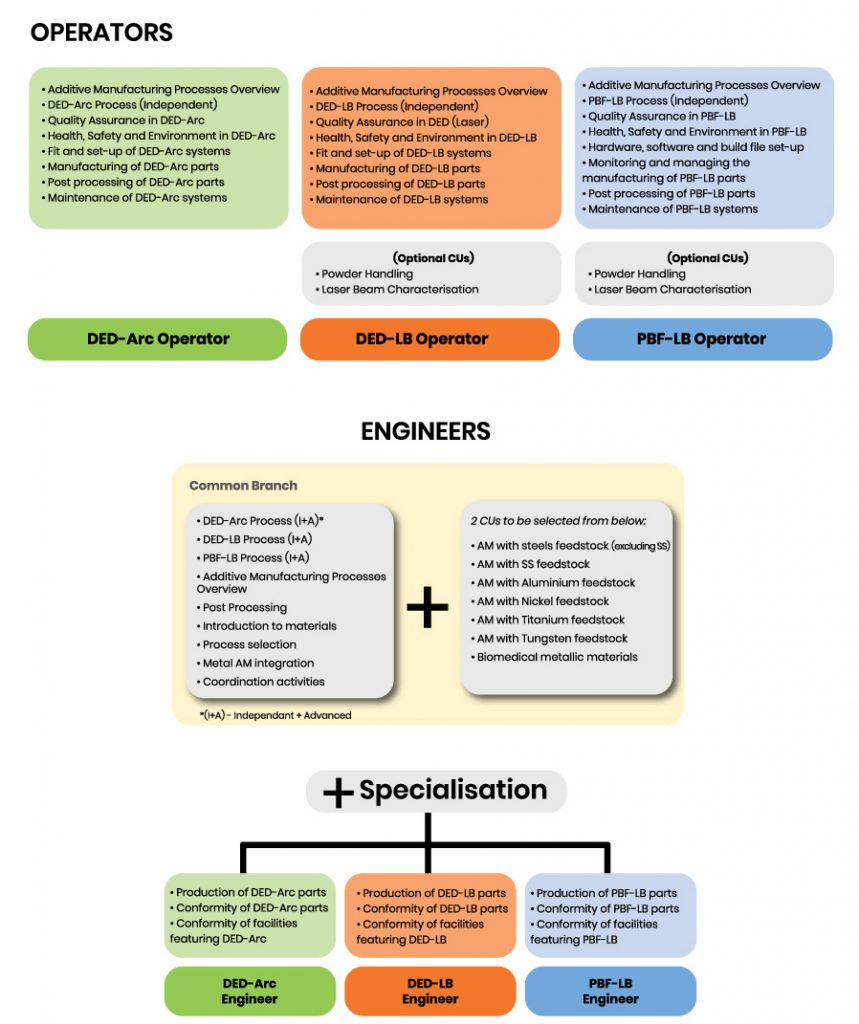

Presently, to train as an operator in either LPBF, DED-LB or DED-Arc there are eight modules:

– Process overview

– Process (Independent)

– Quality assurance

– Health, safety and environment

– Fit and set-up

– Parts manufacturing

– Post processing, and

– System maintenance

For laser based processes, there are also two optional competence units, relating to powder handling and laser beam characterization.

In the second qualification, for engineers, process overviews, independent and advanced process, and post processing training is given for all three technologies. This is then compounded by an introduction to materials, process selection & integration, and co-ordination activities. After this introduction, the direction is then determined by the trainee’s specialism. There is the option to select competence units relating to specific material feedstock, (nickel, titanium, biomedical materials etc.) and followed by modules related to the method of choice, i.e. DED-Arc, DED-LB or LPBF.

The operator course is best suited to personnel looking to gain AM processes knowledge. The engineer qualification, on the other hand, is for “professionals who wish to be responsible for the implementation and coordination of AM activities.”

Skills and collaborative learning for European manufacturing

The development of the International Qualifications System for Additive Manufacturing was co-ordinated by EWF under the Sector Skills Strategy in Additive Manufacturing (SAM) project, which is funded by the European Commission. Brunel University London and the Hanover-based LZH Laser Akademie GmbH developed the system, in collaboration with 16 other partners from industry and education.

The EWF’s Industry Survey on AM Skills is also part of the SAM project, and will be used by the collective to the help create a shared skills vision and collaborative learning solutions for Europe’s manufacturing sector.

Source: 3dprintingindustry