The U.S. Army Combat Capabilities Development Command (CCDC) of the Army Research Laboratory (ARL), is using customized steel alloy powder to 3D print high-strength spare parts for ground vehicles in a bid to “to revolutionize logistics.”

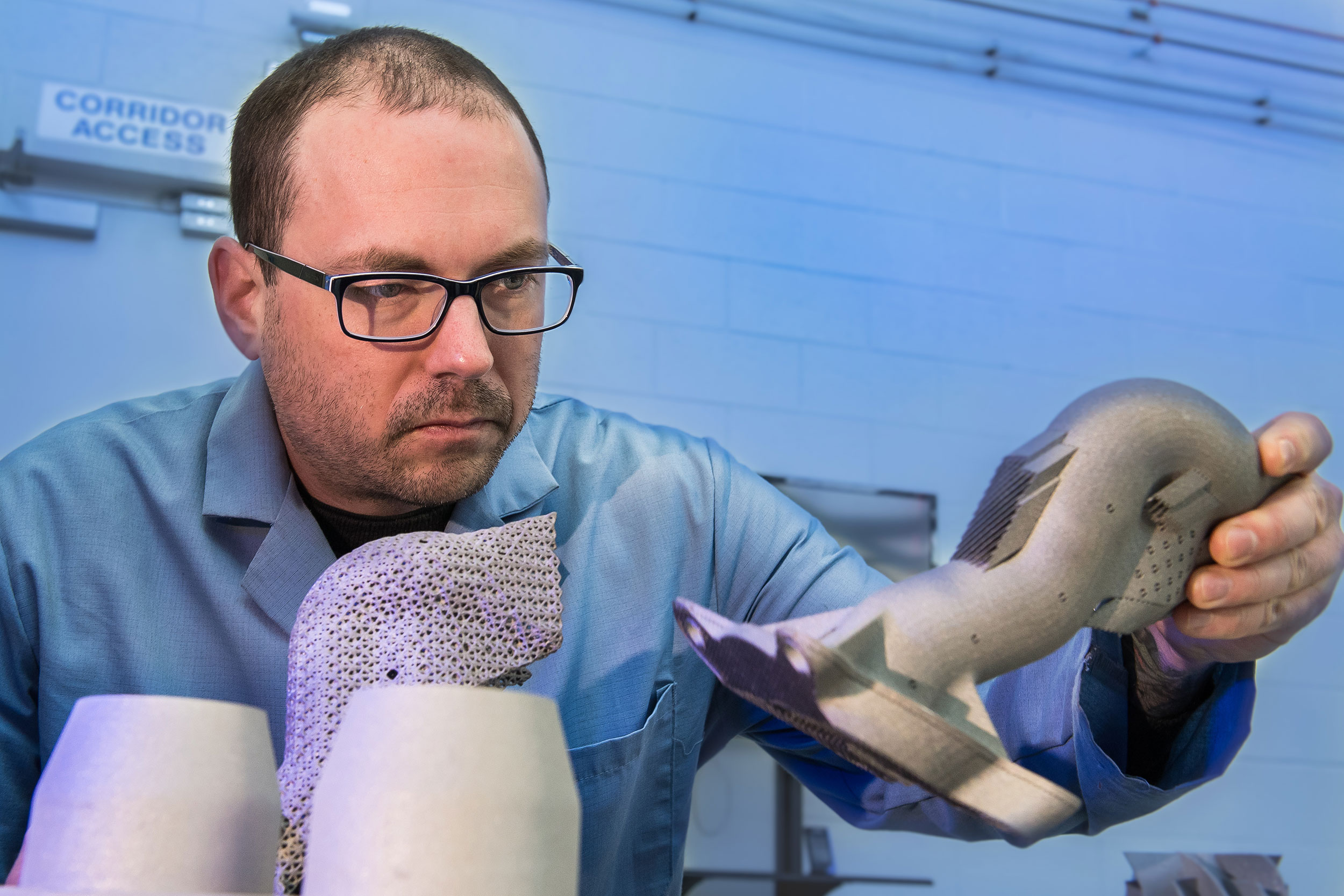

“Additive manufacturing is going to have a huge impact on sustainment,” said Dr. Brandon McWilliams, a team lead in ARL’s manufacturing science and technology branch. “We’ve printed some impeller fans for the M1 Abrams [an American main battle tank] turbine engine and we can deliver that part – they can use it, and it works.”

With the Laser Powder Bed Fusion (LPBF) process, the alloy AF96, a material originally developed by the U.S. Air Force, is being applied by Dr. McWilliams and CCDC researchers to create vehicular components said to be 50% stronger than commercially available equivalents.

A stronger, military-grade metal

The U.S. Air Force initially developed AF96 for bunker-busting bomb applications. It is an accessible metal, in terms of its handling, and exhibits very high-strength and hardness.

Now AF96 has been adapted for army applications particularly, for the replacement of army vehicle parts and the development of future systems. “A lot of our parts in ground vehicles now are steel,” explained Dr. McWilliams. “So [metal 3D printed parts] could be dropped in as a replacement not having to worry about material properties because you know it’s going to be better.”

As a proof of concept, the CCDC has 3D printed AF96 impeller fans, which are used to cool the fan motor in a tank engine. Within the M1 Abrams tank’s engine, these fans allow air to flow evenly, controlling the temperature of the vehicle. With the ability to remotely 3D print AF96 parts such as these, the CCDC hopes to reduce the strain on the army’s logistics chain.

“Instead of worrying about carrying a whole truckload, or convoys loads of spares,” adds Dr. McWilliams, “as long as you have raw materials and a printer, you can potentially make anything you need.”

Nonetheless, the researchers understand the hurdles of qualification for new materials. “In terms of a battlefield scenario [this] may be good enough to be able to get your tank running again for hours or days if that’s important to the mission, but on the other hand, we still need to be able to answer, does this perform as good as the OEM part? Does this perform better?”

“That’s where we’re more integrated with the OEMs and industry to see the things they’re working on and see how we can make things better to really push the state-of-the-art.”

Advancing alloys

CCDC researchers, as well as academic researchers, are working to model AF96 and other alloys for high-performance materials that can be readily available to soldiers. For example, in 2018, material scientists from the ARL also commenced research into nickel-titanium alloys for stronger, more heat-resistant 3D printing materials.

Prior to this, the ARL funded two metal 3D printing projects at the University of Texas at El Paso (UTEP) seeking to develop a method of monitoring and auto-correcting powder-bed fusion based processes, enhancing the mechanical properties of metal parts through nitride coating.

As a result of this most recent demonstration by the CCDC, researchers have now developed a road map focused on supporting their modernization priorities, while closely tied to the ground combat vehicle community.