California-based metal additive manufacturing technology company VELO3D has made enhancements to its Flow print preparation software.

VELO3D’s Flow software is designed specifically for its Sapphire System, a laser powder bed metal additive machine. The software works to determine predictable print outcomes using an integrated simulation engine. In addition, its CAD workflow UI controls performance to reduce print preparation time.

“Flow takes a refreshing new look at additive software: its ease of use is unprecedented. Understanding how users work and offering just in time tools is an exciting direction taken by VELO3D,” said Scott Volk, CTO of Incodema3D.

“VELO3D’S ADVANCED SIMULATION, PREDICTION AND CORRECTION ENSURES NOT ONLY PRINT SUCCESS, BUT IMPROVED PART TO PART QUALITY ACCELERATING THE ADOPTION OF VOLUME PRODUCTION.”

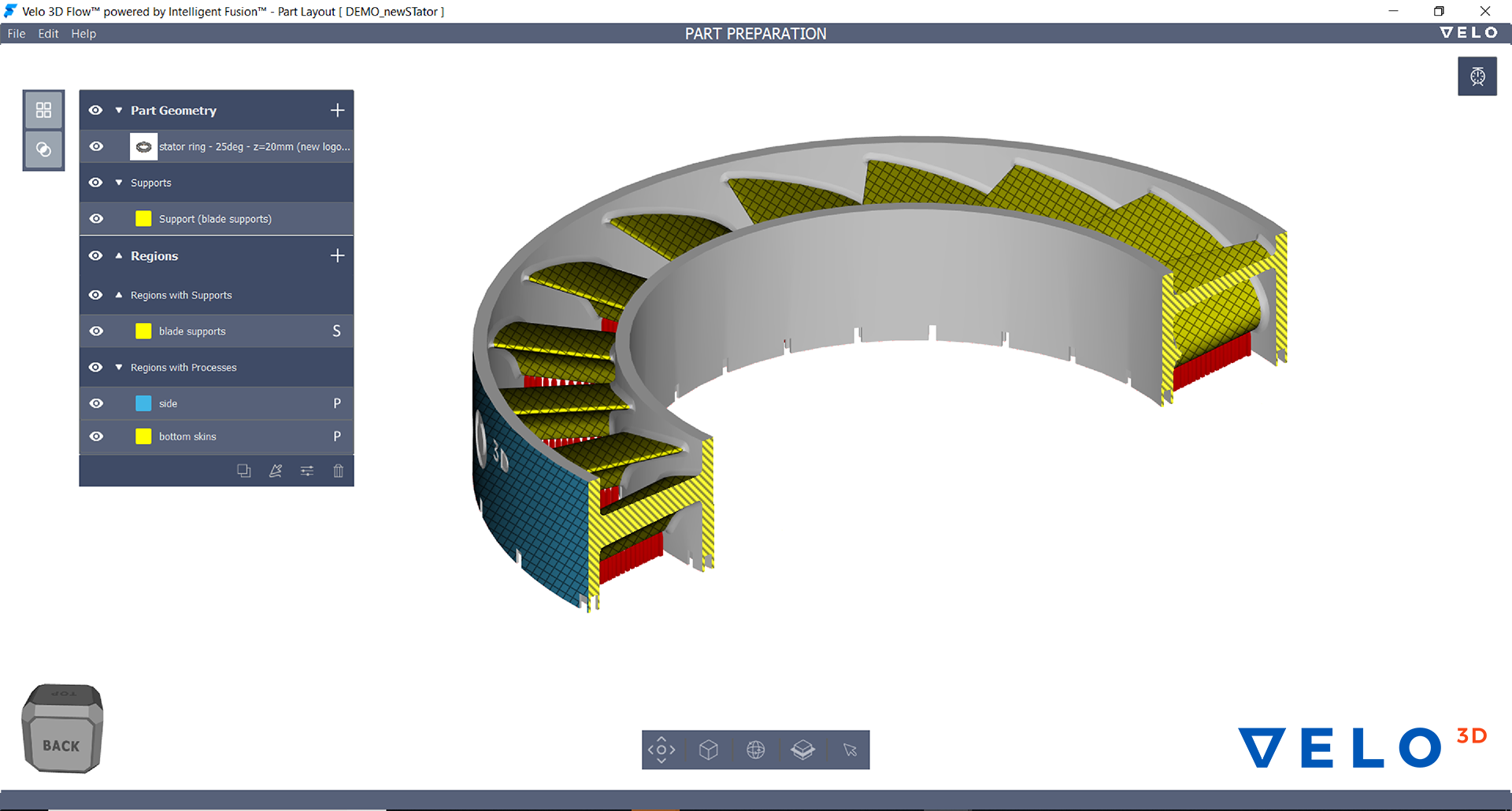

Complex metal 3D printing with Flow and Sapphire technology

Flow software, in conjunction with the Sapphire System, includes tools that help with part orientation, support generation and simulated print predictions.

A new feature of Flow is a physics-driven simulation engine, optimized for use with the Sapphire System. VELO3D claims the simulation engine contributes to achieving a first print success rate of up to 90%.

VELO3D’s Flow simulation utility uses print deformation correction and validates execution feasibility. This helps to predict print outcomes prior to starting the build process, ensuring dimensional accuracy with the design intent. The software also has a composer that applies optimized print processes to specific geometric features that it detects.

VELO3D’s technology additionally aims to allow manufacturers to 3D print parts with complex geometries without the need for supports. Angles down to 5°, large inner diameters and tubes up to 40mm can be printed using the Flow and Sapphire technologies without supports. This enables the volume manufacturing of parts that would otherwise be difficult and uneconomical to print, eliminating the need for post-processing cleanup.

“Build preparation software has always been an afterthought,” comments Benny Buller, CEO of VELO3D. “VELO3D’s strategy is to offer an integrated hardware, software and process solution.”

“THE SYSTEM IS PROCESS DRIVEN, WHERE THE SOFTWARE MANAGES THE HARDWARE AND CAN PREDICT AND CONTROL THE OUTCOME. IT IS THE ONLY WAY TO FULFILL OUR MISSION TO MANUFACTURE ANY DESIGN, ASSURE ACCURACY AND CONSISTENCY AND THUS TAKE ADDITIVE MANUFACTURING MAINSTREAM.”

Simulation software enhancing additive manufacturing

VELO3D’s announcement follows a trend in improvements for 3D printing simulation software development. Multinational aerospace company, BAE Systems, recently selected the Simufact Additive simulation software developed by California-based technology company MSC. The software was chosen by BAE systems for use in metal 3D printing, specifically to reduce the number of build trials through simulation.

Source: 3dprintingindustry