Blue Origin, LLC, the private American aerospace company of Amazon CEO Jeff Bezos, has started building a factory in Huntsville, Alabama for its 3D printing-inclusive rocket engines.

Set to open in 2020, the new facility will cost $200 million to build and is expected to create hundreds of jobs for the local industry.

The focus of the plant will be series production of the company’s BE-4, tipped to be “the most powerful liquefied natural gas (LNG) fueled rocket engine ever developed.” Speaking to regional news site AL.com, Blue Origin CEO Bob Smith said that, at the site, “We’re going to be producing dozens of engines a year.”

Hundreds of 3D printed parts destined for spaceflight

Founded in the year 2000 Blue Origin, like close competitors Virgin Galactic and SpaceX, is focused on giving private individuals access to space, and creating reusable suborbital and orbital vehicles.

Over almost two decades, the company has gone through three generations of engine, each incrementally rising in thrust. It has also developed the New Shepherd flight vehicle which, according to Blue Origin Senior Vice President Rob Meyerson, contains “over 400 additively manufactured parts.” January 23, 2019, marked the 10th successful mission for the New Shepard program and the 4th flight for the vehicle, carrying a NASA research payload.

Recently, the company announced its development of the New Glenn reusable, orbital launch vehicle. With the help of the new rocket engine factory in Alabama, the New Glenn is scheduled for launched in 2021, alongside the United Launch Alliance (ULA) Vulcan rocket which will also house the Blue Origin BE-4 engine.

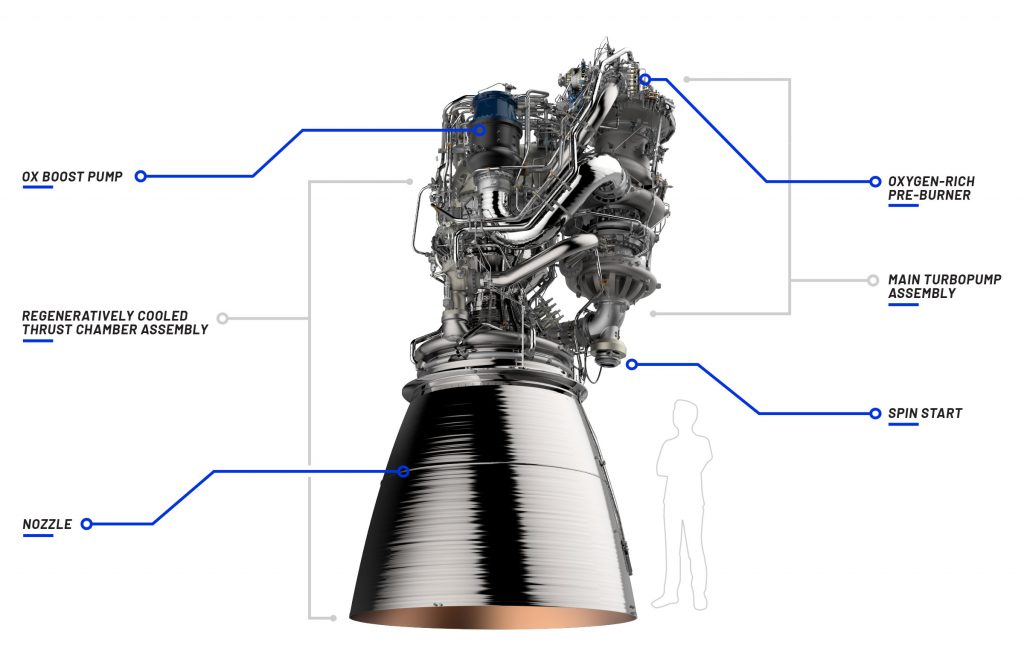

Inside the BE-4 engine

The BE-4, like the ArianeGroup’s Prometheus, is a liquid oxygen (LOx)-methane engine. At this stage of development, Blue Origin has confirmed that the BE-4 has been tested to 70% of its expected thrust rate. Currently in development at the company’s premises in Texas, 100% tests of the engine are imminent. At full power, the BE-4 will be capable of producing 550,000 lbs. of thrust.

The assembly line for the BE-4 is reportedly “highly automated” and features a number of advanced manufacturing techniques. Speaking again to AL.com, Smith said, “The engine has a lot of additive parts. It has some very unique cladding and different ways we produce that engine […] All of our things are ‘build to print.’ Everything that you’ll see that’s on that engine is actually going to be built from effectively bar stock or powder that we put into that facility.”

In a statement on the launch of the new BE-4 production facility Tory Bruno, President and CEO of Blue Origin partner ULA, comments, “We look forward to our partnership with Blue Origin, building the advanced BE-4 engine to power our next-generation rocket, right here in Alabama!”

Source: 3dprintingindustry.com