Today, nearly all personal electronic devices rely on antennas to send and receive data. In fact, demand is also rising for lightweight antennas for new applications, including the latest in 5G/6G networks, advanced wearable devices and aerospace applications like CubeSats. However, standard manufacturing techniques have limited the structural complexity and use of multiple materials that would unlock still more features and capabilities from antennas.

Now, a team led by Xiaoyu (Rayne) Zheng — associate professor in UC Berkeley’s Department of Materials Science and Engineering and faculty co-director of Berkeley Sensors and Actuator Center (BSAC) and the Jacobs Institute for Design Innovation — has developed a new 3D printing/additive manufacturing platform that offers “unparalleled flexibility in antenna design and the capability for rapid printing of intricate antenna structures.”

As reported in the latest issue of Nature Communications, the new platform — dubbed charge programmed multi-material 3D printing (CPD) — is a universal system for rapid production of nearly all 3D-printed antenna systems. It can pattern highly conductive metals with a wide range of dielectric materials into a 3D layout.

Zheng emphasized that the platform is not an expensive 3D printer for metals that would involve pricey metal powders and high-energy lasers. “This technology can be applied to desktop-friendly light-based printers,” he said.

The CPD method combines a desktop digital light 3D printer and a catalyst-based technology that can pattern different polymers at different locations where they will attract metal plating. Its auto-catalytic or selective plating technology enables the polymers to selectively absorb metal ions into prescribed locations that are defined by the desired antenna design outcome.

CPD can broadly integrate with a variety of multi-material 3D printing methods, Zheng said. “It allows essentially any complex 3D structure, including complex lattices, and has demonstrated deposition of copper with near pristine conductivity, as well as magnetic materials, semiconductors, nanomaterials and combinations of these.”

A CPD-fabricated gradient phase transmitarray for generating highly directive radiation. The antenna features three layers of gradually tilted architected S-ring unit cells. (Image courtesy of the researchers)

Zheng has been working on the CPD platform since 2019 when his group first came up with the concept. In 2020, his team published their first paper in Nature Electronics on this technology, followed by a 2022 paper in Science that described the use of it to make microrobots.

This latest paper is specific to the antenna application. CPD, Zheng said, is “very uniquely suited for antennas, because nearly all antennas need two components: One is the metal phase, the conductor, and the other is the dielectric phase, which is not conductive — and [until now] there has been no technology capable of directly patterning or synthesizing the conductor and dielectric materials together.”

Zheng explained that the first application they considered was in antennas. After discussing the technology with colleagues who specialize in this area, they realized that this technique could revolutionize how antennas are printed and open many new design possibilities.

Technology Behind 3D-Printed Antenna

Printing both the conductor (metal) and dielectric materials is especially important for antennas to be used in extreme environments. For example, Zheng says, “you cannot use a regular polymer in space. You need a high temperature polymer like Kapton, which is a good material in aerospace [stable at both very high and very low temperatures]. Now you can have Kapton and a pattern of metal traces interwoven in 3D at the same time.”

The team has also shown that through proper 3D designs, these antennas, without having to sit on a bulky substrate, achieve substantial weight savings compared to current antennas.

Co-author Yahya Rahmat-Samii, professor of electrical and computer engineering at UCLA, believes the CPD platform could significantly expand the possibilities for new antenna technologies and enable data-drive designs — allowing out-of-the box antenna designs for diverse applications. “There are probably numerous different antenna structures, depending on the application you have in mind,” he said.

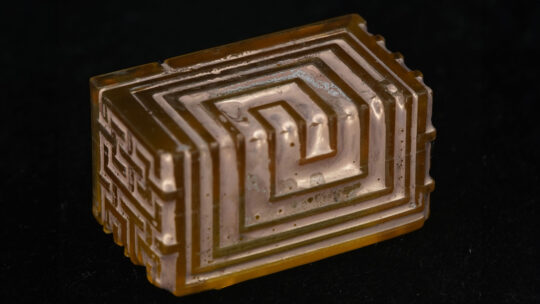

A 3D folded implantable electrically small antenna featuring interpenetrating Archimedean spirals and Hilbert curves. (Image courtesy of the researchers)

Zheng and Rahmat-Samii next want to explore the full complexity of antenna design achievable with their new 3D-printed antenna technology. Control of an antenna’s complexity gives them control over the ability to shape electromagnetic waves, much as a painter controls the application of paint with a brush. Aiming to advance applications for this technology, the team at UC Berkeley has formed a startup company focused on flexible medical sensors that would conform, say, to the shape of a hand.

“We can achieve a tunable antenna,” Zheng says. “And so the question now is, where can that technology help us best with regard to 3d-printed antenna ?