Franco-Italian aerospace manufacturer Thales Alenia Space is to use 3D printing in the series production of its satellites. Applied to the company’s Spacebus NEO platform, the first run of these additively manufactured components has already been integrated into a commercial satellite project for Eutelsat Communications, which is set to launch by the end of 2019.

Philippe Sicard, Satellite Quality Resident and Eutelsat Engineer, comments:

“EUTELSAT IS NOW FULLY INVOLVED IN THE DEVELOPMENT AND USE OF 3D PRINTED SATELLITE PARTS AT ALL STAGES OF THE PROCESS, FROM DESIGN TO FINAL DELIVERY.”

“These parts are recognizable by their highly specific design. And to ensure the most stringent quality standards, the overall process and individual components are robustly traceable and we have set up a comprehensive testing and inspection process.”

Faster broadband for Western Europe and Africa

The Spacebus NEO platform at Thales Alenia Space is a line of all-electric geostationary telecommunications satellites. Its development is jointly supported by the European Space Agency (ESA) and CNES, France’s National Centre for Space Studies.

The Eutelsat KONNECT is the first satellite to make use of the new Spacebus NEO platform. Made to provide faster broadband connection to areas of Western Europe and Africa, the KONNECT is still under construction. When completed it will be capable of handling payloads exceeding 1,400 kg, with over 16 kW of power.

In the most recent update on this program, Eutelsat confirmed the successful coupling of the KONNECT’s platform and its payload – a crucial step in the satellite’s preparation.

More 3D printed parts still to come

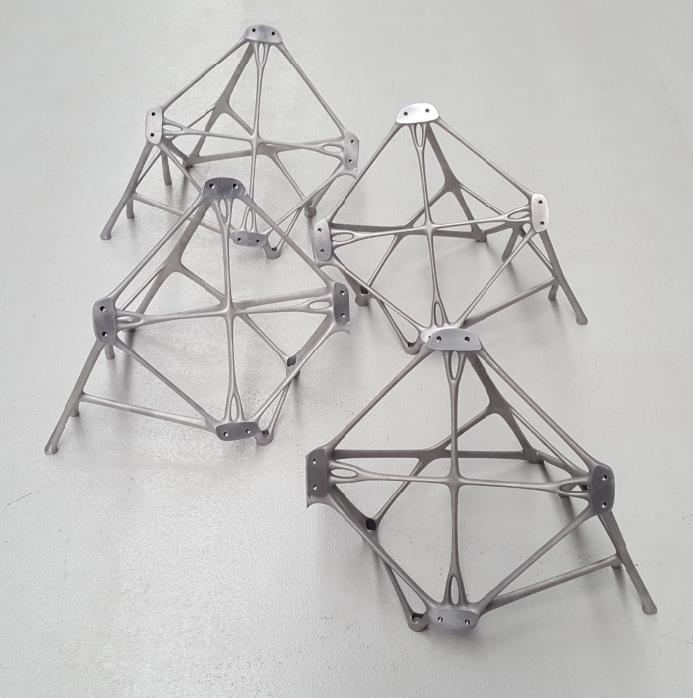

3D printed parts for the KONNECT satellite currently include four custom-designed reaction wheel brackets. Manufactured in a single part, these brackets incorporate connector and cable fittings, cutting out the need for assembly. By switching to 3D printing for the production of these parts, Thales has managed to deliver a 10% cost saving, shorter lead times, and an overall weight reduction of 30%, all while increasing performance.

The parts are additively manufactured on a Xline 2000R 3D printer from Concept Laser, a GE Additive company. This machine has been in use at the company for several years, previously used in the development of other components, including antenna supports.

Based on the successful installation of the KONNECT wheel brackets Alenia Space says “Other Spacebus Neo platforms will also feature organically designed 3D printed parts in the near future.”

The company is also currently involved in the maturation of wire + arc additive manufacturing (WAAM) technology as part of the WAAMM at consortium. Earlier this month, the company unveiled a prototype pressure vessel made as part of this program. Related technology used to make the vessel is due for commercial release later this year.

Source: 3dprintingindustry