Stratasys, the inventor of FDM 3D printing technology, has made its entry into SLA for the first time. In the second of two product launches from the company at this year’s Additive Manufacturing User’s Group (AMUG) Conference, the V650 Flex was unveiled in Chicago yesterday. Reporting live from the conference all week, 3D Printing Industry was among the first to see the machine on initial public display.

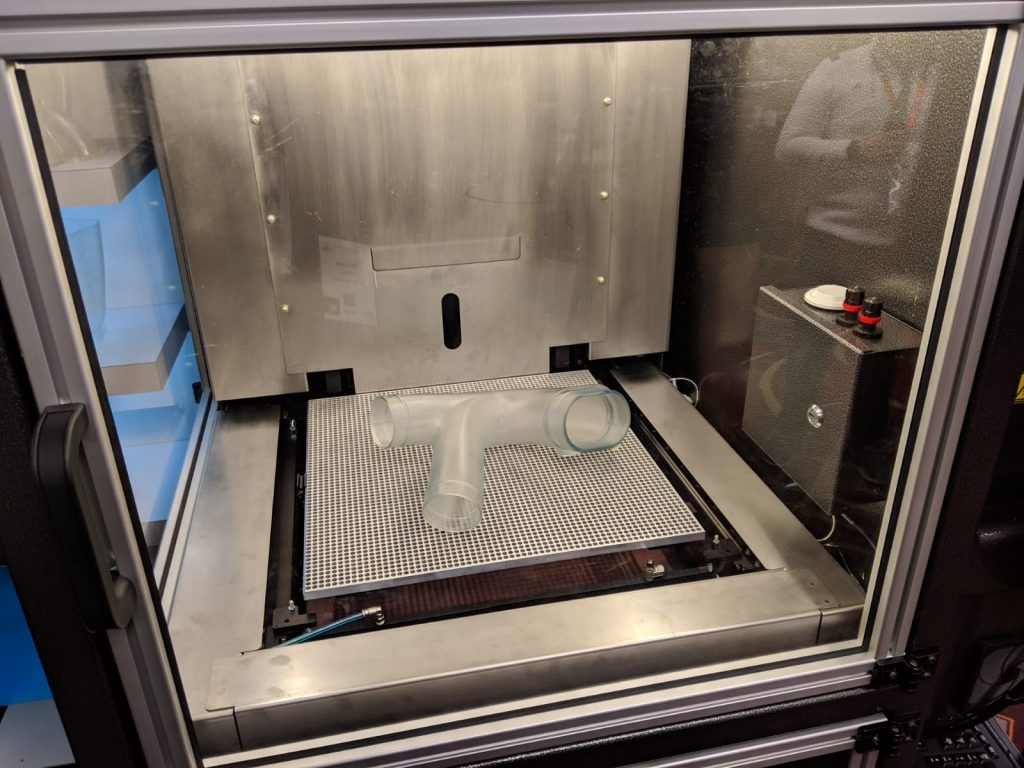

Displayed alongside the new F120 3D printer, Stratasys’ latest addition to the F123 range, the V650 Flex is a large-scale, industrial SLA machine, operating a build volume of 508 x 508 x 584 mm (W x D x H). Inline with the Stratasys household name, the system promises the utmost reliability. Its release has also been backed by a materials partnership with Global science company, DSM. Hugo da Silva, VP of Additive Manufacturing at DSM, comments,

“STRATASYS’ ENTRANCE INTO THE STEREOLITHOGRAPHY SEGMENT IS REALLY A GAME-CHANGER FOR THE INDUSTRY.”

“Our collaboration allows customers to have greater access and flexibility for development of durable and reliable prototypes and tooling using stereolithography 3D printing.”

V650 Flex technical specifications and materials

The Stratasys V650 Flex has been 28 years in the making. According to the company, for almost three decades, this system has been behind SLA 3D print requests of the Stratasys Direct Manufacturing service. In this time, the machine has completed a rigorous test run of over 75,000 hours, producing more than 150,000 parts.

As per the name, this machine offers full user-flexibility. It is an open-materials platform, working with third party resins, and can be used by operators to develop new feedstocks. The machine also promises to be fully configurable, enabling a great deal of fine tuning to the process. This includes an adjustable beam spot size from 0.005” to 0.015”.

Not one to leave its customers without a full ecosystem however, and with DSM as a launch partner, Stratasys will be selling resins from the Somos range of materials for use with the V650 Flex. “From the high-performance demands of automotive and aerospace industries to the durability and flexibility requirements of consumer goods, customers worldwide rely on Somos materials to create the highest-performing additive manufacturing prototypes and tools,” comments da Silva. On launch, DSM materials available through Stratasys are:

– Somos® Element, designed for investment castings

– Somos® NeXt, a strong, thermoplastic-like resin

– Somos® PerFORM, stiff, strong, composite material and,

– Somos® Watershed XC 11122, a low-viscosity photopolymer, with ABS-like properties

Responding to customer demand

The vat of the V650 Flex is interchangeable, reducing 3D printer downtime in-between builds. Though operating a competitively-large build chamber, the machine boasts a relatively small footprint, measuring 4.5 ft wide by approximately 7 ft high. It also runs on 110V power.

As with all Stratasys systems, one of the biggest selling points for some is the aftercare that the company provides. Omer Krieger, EVP Products at Stratasys, comments, “The Stratasys on-demand network of service personnel and resellers is designed to enable customers to achieve much more through stereolithography than they have in the past.”

As a well-established brand for FDM 3D printers, and a known-name throughout the industry, many have questioned why Stratasys has chosen to launch an SLA system and why now. Somewhat substantiating this move Krieger adds, “While stereolithography is one of the original 3D printing processes – mainly used to create master patterns or large concept models quickly and accurately – customers have been challenged by restricted systems that can’t be configured and materials at a high cost-per-part.”

“THE V650 FLEX IS THE RESULT OF CUSTOMER DEMAND AROUND THE WORLD WANTING A BETTER SOLUTION – FULLY CONFIGURABLE TO MATCH THE SPECIFIC APPLICATION AND USE-CASE.”

“The solution is truly one of the first large-scale systems for creating reliable, high-quality parts across design concepts, validation, investment casting, tooling, and injection molding.”

Source: 3dprintingindustry