Engineers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) have used 3D printing to build a robotic device capable of gripping a wide range of objects.

The findings of the research were published in a paper titled, A Vacuum-driven Origami “Magic-ball” Soft Gripper.

Co-author of the paper and Professor at Wyss Institute for Biologically Inspired Engineering, Robert Wood, said, “One of the key features of this approach to manipulator construction is its simplicity.”

“THE MATERIALS AND FABRICATION STRATEGIES USED ALLOW US TO RAPIDLY PROTOTYPE NEW GRIPPERS, CUSTOMIZED TO OBJECT OR ENVIRONMENT AS NEEDED.”

Origami magic ball

In robotics research, 3D printing is proving a competent method for testing prototypes and manufacturing fully functional devices. Examples of recent research in soft robotics, modular robots, and Wyss Institute‘s bioinspired robotic hand for studying fauna have emphatically brought this point forward.

The latest research was founded upon the team’s previous concept called Fluid-driven Origami-inspired Artificial Muscle (FOAM). The FOAM consists of an airtight skin and a malleable skeleton structure which contracts under negative pressure.

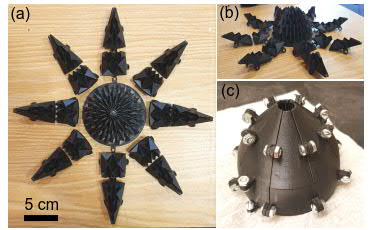

The newly created ‘magic ball’ gripper works on the same principle as FOAM and is inspired by origami magic ball. The magic ball gripper is smaller in size with increased skin constriction, which increases the strength of the grip.

A little help, please

Three different prototypes of the ‘magic ball’ were made, with different material and dimensions. Using the Stratasys Fortus 400, the research team 3D printed molds in ABS to cast the gripper. Two of the grippers were cast in silicon rubber and one was made with PET/PVC/Kapton composite and TPU coated nylon.

Co-author of the research and MIT professor Daniela Rus talked about her future vision for such robots. Rus said, “One of my moonshots is to create a robot that can automatically pack groceries for you.”

Shuguang Li, a joint postdoc at MIT CSAIL and Harvard‘s John A. Paulson School of Engineering and Applied Sciences (SEAS), elaborated further, “Companies like Amazon and JD want to be able to pick up a wider array of delicate or irregular-shaped objects, but can’t with finger-based and suction-cup grippers” […] “Suction-cups can’t pick up anything with holes – and they’d need something much stronger than a soft-finger-based gripper.”

Grip anything

The grippers were attached to a Baxter industrial robot and were tested using 3D printed objects. These objects were mounted to an Instron machine, so the weight of the object itself was immaterial to the study of stress, tension, and pressure.

Objects ranging from fruits like grapes, mushroom, and coke bottles were lifted using the magic ball gripper. It was shown that the gripper can lift up to 2 kg.

Rus explained, “Previous approaches to the packing problem could only handle very limited classes of objects — objects that are very light or objects that conform to shapes such as boxes and cylinders, but with the Magic Ball gripper system we’ve shown that we can do pick-and-place tasks for a large variety of items ranging from wine bottles to broccoli, grapes and eggs.”

“IN OTHER WORDS, OBJECTS THAT ARE HEAVY AND OBJECTS THAT ARE LIGHT. OBJECTS THAT ARE DELICATE, OR STURDY, OR THAT HAVE REGULAR OR FREE FORM SHAPES.”

The research discussed in this article is titled, A Vacuum-driven Origami “Magic-ball” Soft Gripper, published in the Proceedings of the 2019 IEEE International Conference on Robotics and Automation. The authors of this paper are Shuguang Li, John J. Stampfli, Helen J. Xu, Elian Malkin, Evelin Villegas Diaz, Daniela Rus, Robert J. Wood.

Source: 3dprintingindustry