3YOURMIND, the Berlin-based software provider for industrial 3D printing processes has extended their partnership with the Deutsche Bahn. Deutsche Bahn is using the software solutions from 3YOURMIND to collect promising 3D printing applications from throughout their company in order to assemble a digital spare parts warehouse.

3YOURMIND develops software solutions to optimize the processes of industrial 3D printing. Their platforms enable customers to fully exploit the potential of 3D printing with digital workflows that connect teams and production sites. The software algorithms also optimize machine utilization and enable data-based production decisions. 3YOURMIND works closely with customers to add efficiency to AM processes within the company and drive AM production forward.

Deutsche Bahn has been working intensively for five years to develop their 3D printing division. At the end of 2015, DB had produced a coat hook as their first replacement part from a 3D printer, the same hooks that every DB passenger recognizes in the train compartments. By the end of 2018, DB had printed almost 15,000 spare parts and other products and now intends to expand even further. The software solution from 3YOURMIND supports DB’s ambitions to collect 3D printing ideas from across the nation, standardizes the submission process and identifies the strongest results. Deutsche Bahn and 3YOURMIND are joined in a strategic partnership to expand DB additive manufacturing.

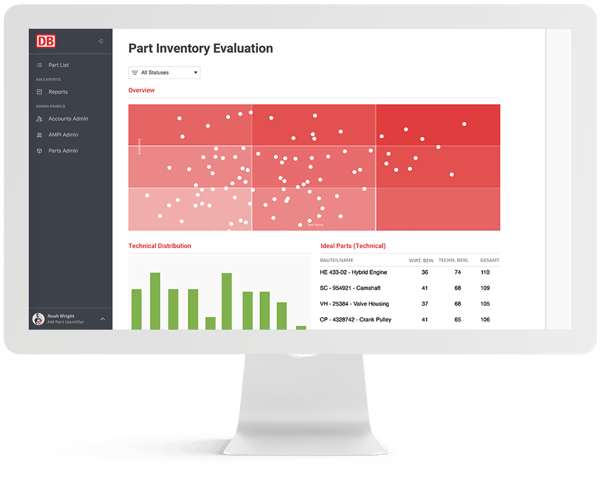

The software from the Berlin experts allows DB employees to propose potential 3D printing applications they encounter in their daily work using a simple digital interface. Within seconds, the employees can submit their new ideas. The software provides an analysis of the ideas and identifies the use cases with the highest production potential. A team of experts from Deutsche Bahn will then select the best projects to move into production and provide recognition to the submitter. The goal for Deutsche Bahn is to educate employees about additive manufacturing. The AM Part Identifier software is part of a “3D printing employee challenge” across their organization. They expect to bring together existing and emerging knowledge about 3D printing from within the DB network and raise the attention of employees to gather ideas.

Already, 3D printing applications are achieving significant savings at DB and even more importantly, they are helping to reduce vehicle downtime. The most interesting applications are use cases related to spare parts. For trains over twenty-five years old, there are often no suppliers to provide replacement parts and in many cases, there are not even technical drawings available. That makes 3D printing a very interesting technological solution.

DB is beginning the journey to a full digital spare parts warehouse beginning with the most important applications and continuing to expand by adding parts and assemblies. The 3YOURMIND software solutions support Deutsche Bahn in their plans to expand industrial 3D production; from simple interactions with employees to optimized production processes that provide a continuous value to the company.