Multinational chemical company BASF has invested $2 million into the Alchemist Accelerator through BASF Venture Capital GmbH (BVC), to drive new technologies such as 3D printing.

The Alchemist Accelerator is a new venture-backed initiative focused on developing seed-stage technology-based ventures that monetize from enterprises (not consumers). According to BASF, approximately half of this investment will go to additive manufacturing, as well as materials informatics, nutrition and agricultural technology (agtech).

“Alchemist has built a strong reputation for attracting the best in the digital ecosystem. We are thrilled to officially join Alchemist as a Limited Partner,” said Markus Solibieda, Managing Director at BVC.

“DIGITALIZATION REPRESENTS UNPRECEDENTED OPPORTUNITIES TO CREATE VALUE FOR OUR CUSTOMERS AND DEVELOP NEW BUSINESS MODELS. BY INVESTING IN A DIGITALLY-FOCUSED FUND, WE PROMOTE INNOVATIONS AT THE INTERSECTION OF CHEMICALS AND TECHNOLOGIES LIKE ARTIFICIAL INTELLIGENCE, INTERNET OF THINGS AND ROBOTIC.”

The Alchemist Accelerator

Alchemist Accelerator, the Californian venture-backed business incubator, was established in 2013. It seeds 75 startups a year and provides a structured path toward their first customers and fundraising.

As a result of this initiative, 24 companies have been acquired and received funding from capital ventures. This includes Andreessen Horowitz, Bessemer Venture Partners, and Draper Fisher Jurvetsonone. The 6-month program offered from Alchemist provides ventures with enterprise coaches, early adopter customers, and investors.

BVC will act as a Limited Partner in the Alchemist Accelerator. The company’s main objective is to promote innovations at the intersection of chemicals and technologies. Ravi Belani, Managing Director at Alchemist, added:

“It is an honor to welcome BASF Venture Capital as a Limited Partner with Alchemist. Some of the most exciting innovations we are seeing are at the nexus of the digital and material – few partners are as equipped to bring expertise in that area as BASF.”

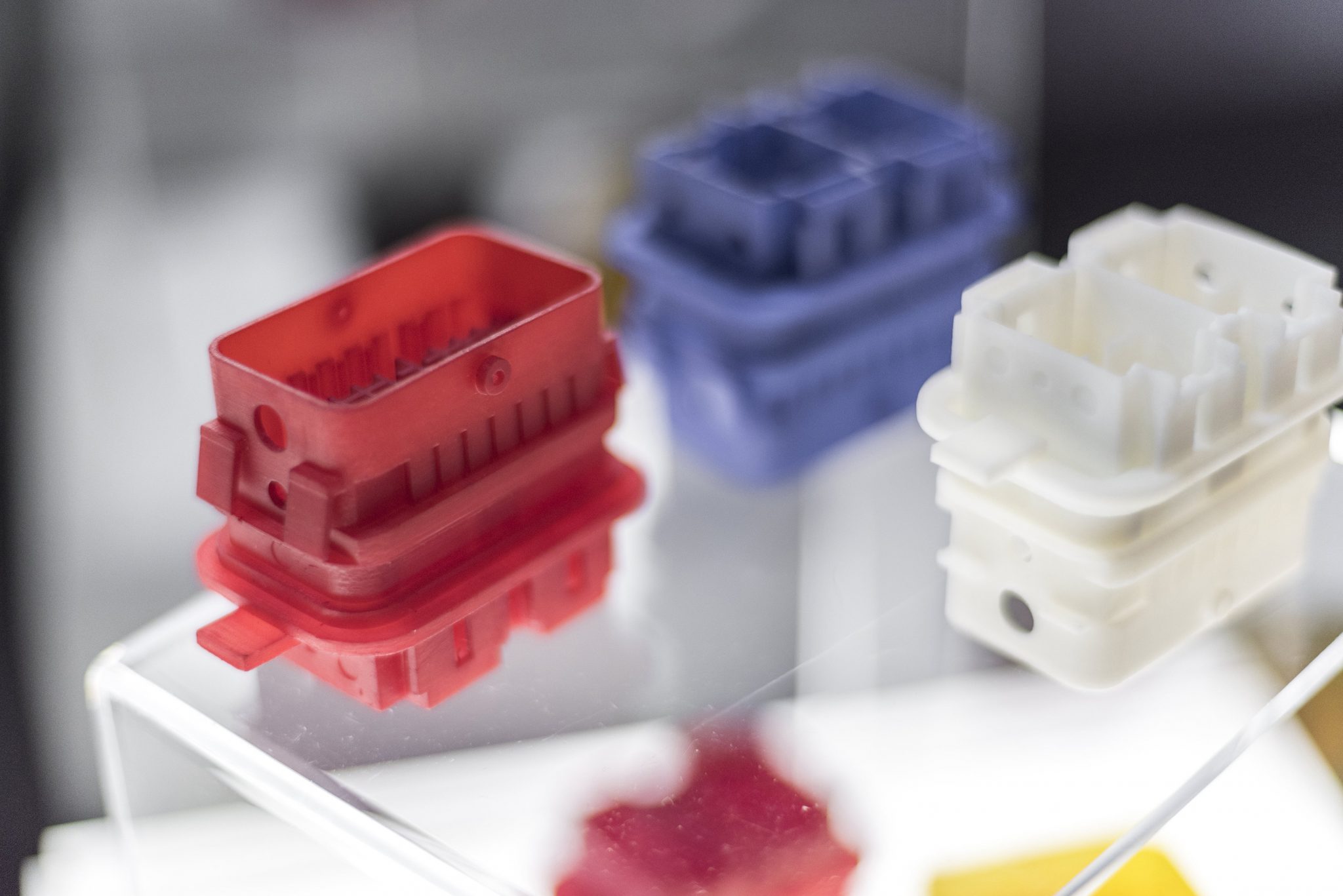

The value of additive manufacturing materials

As the largest chemical producer in the world, BASF has identified the value and invested in the developing additive manufacturing market. Last year, the company acquired two material companies, Advanc3D Materials and Setup Performance to strengthen its presence in the market area of powder bed fusion.

Following this, BASF partnered with Origin, a silicon valley additive manufacturing startup, to optimize a range of photopolymers and additive materials, creating new options for high volume manufacturers.

After, BASF 3D Printing Solutions (B3DPS), a subsidiary of BASF, debuted a new range of photopolymer and laser sintering materials as well as several strategic partnerships at Formnext.

Source: 3dprintingindustry